Developing

Low-Carbon Cement

Green360 Technologies is developing innovative low-cost, low-carbon cement formulations, utilising high-quality metakaolin and industrial byproducts to reduce reliance on traditional Portland cement, a major polluter.

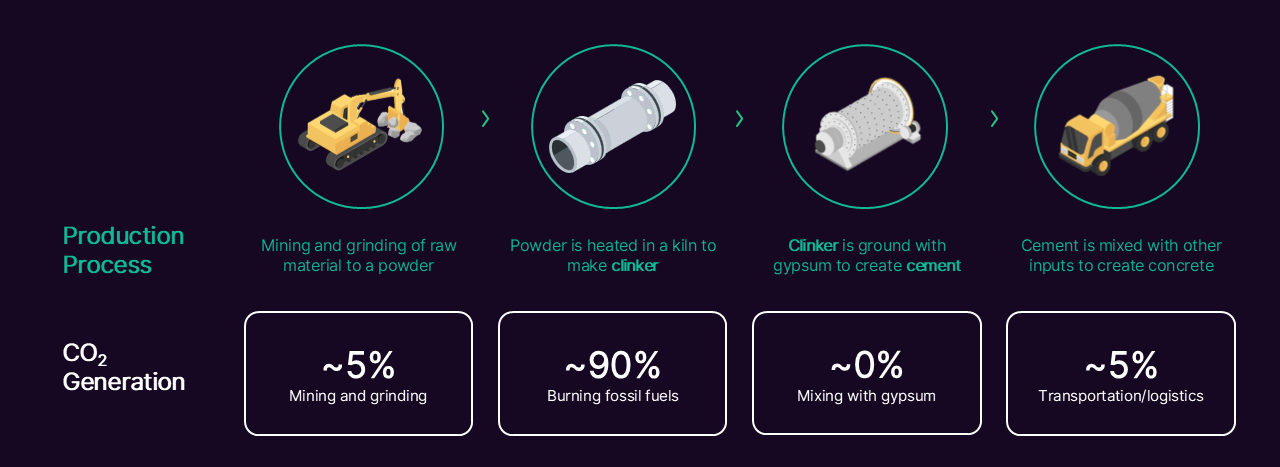

The Problem –

Traditional Cement is a Polluter

The Solution – Low-Carbon Cement

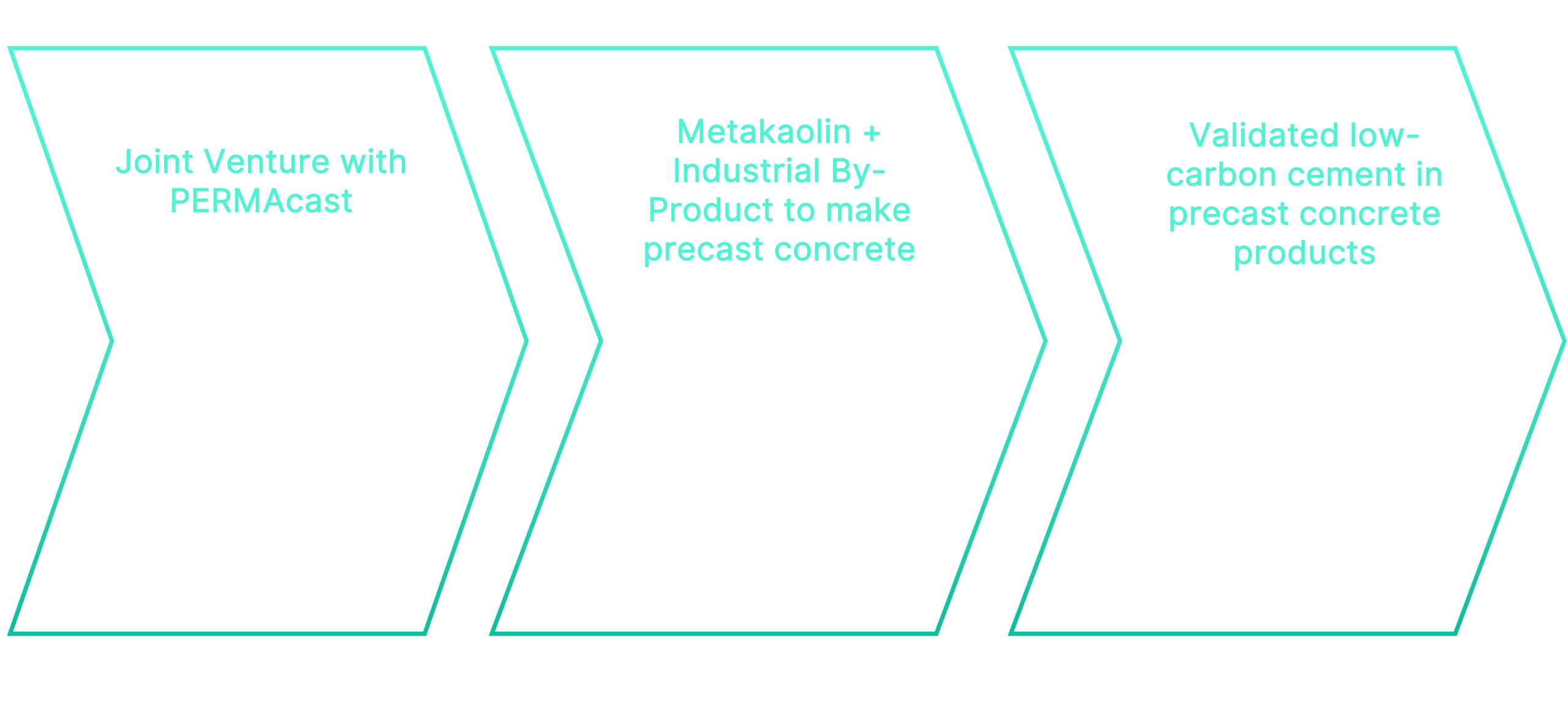

Product Validation with PERMAcast

Partnered with WA’s leading supplier of precast concrete products to validate low-carbon cement formulations

Pathway to Suppling Western Australia

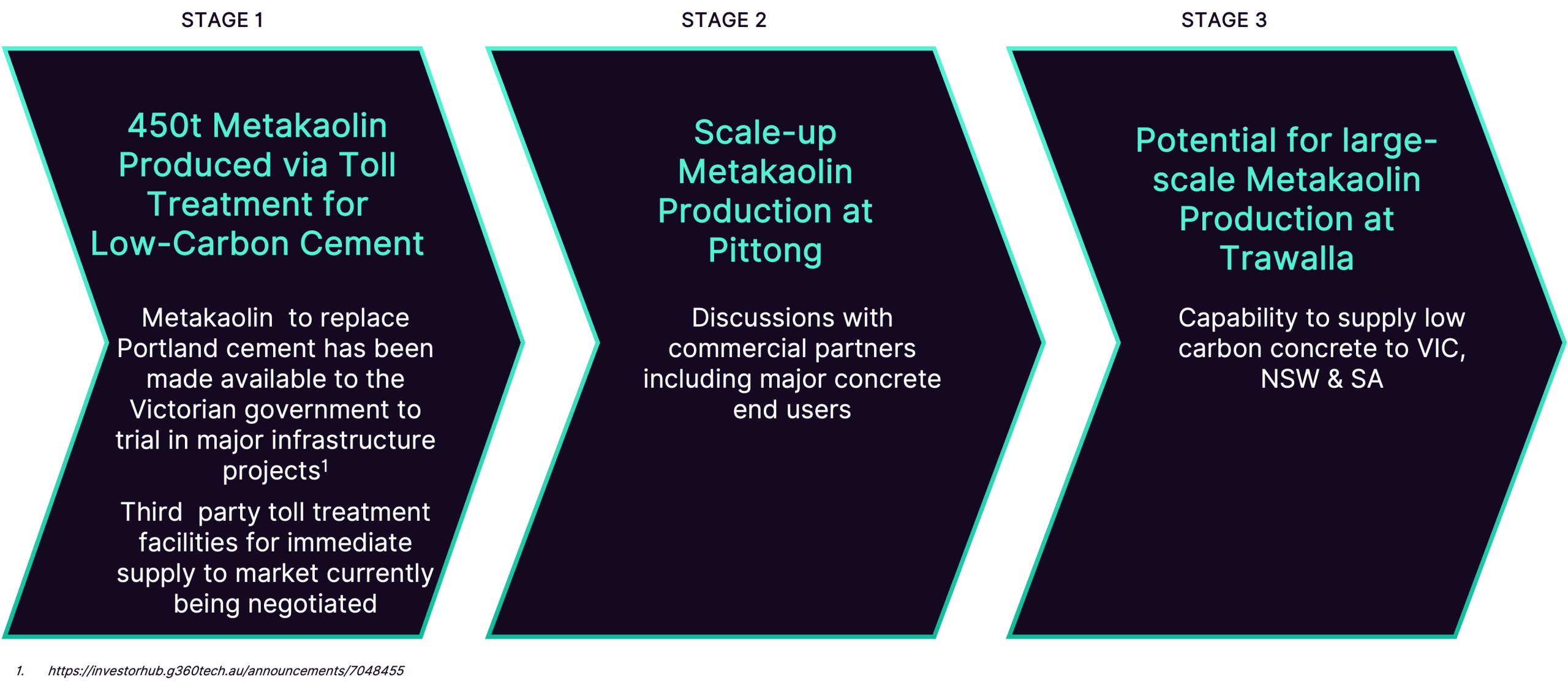

Pathway to Suppling East Coast Markets